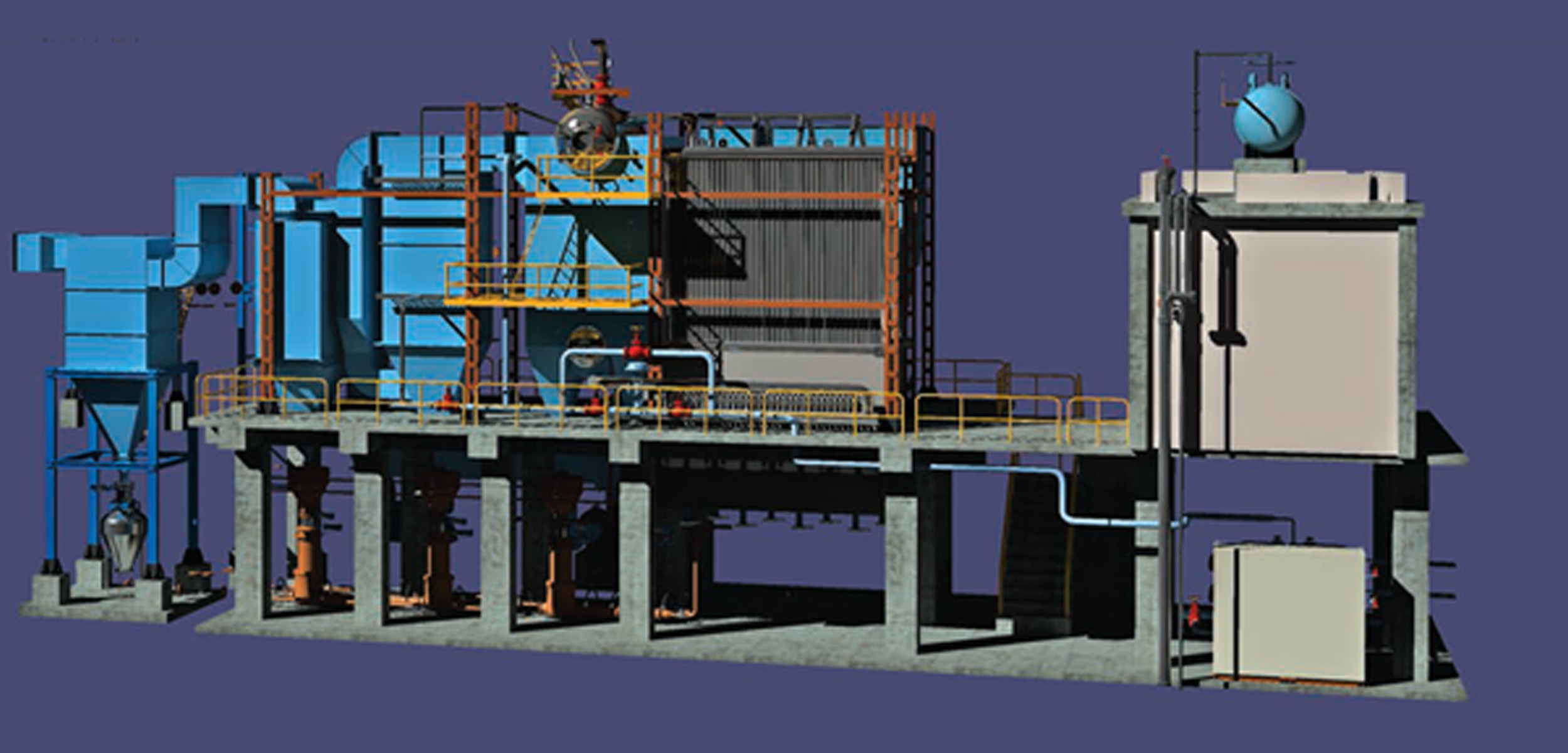

BIDRUM BOILERS- (AFBC & BFBC)

Emperor Bidrum boilers are the Process cum Power necessity

-

When air or gas is passed through an inner bed of solid particles such an sand supported on a fine mesh of grid, the air initially will seek a path of least resistance and pass upward through the sand.

-

With further increase in the velocity, the air bubbles through the bed and the particles attain a state of high turbulence

-

Under such conditions, the bed assumes the appearance of a fluid and exhibits the properties associated with a fluid and hence the name “Fluidized Bed”.

These type of boilers can easily take the variation of load fluctuation without affecting the Overall performance & efficiency of the boiler.

Operating Range

-

Capacity: 8 to 25 TPH

-

Firing Mode : Fluidized bed Combustion ( AFBC,BFBC with over bed & under bed)

-

Pressure : Upto 32 Kg/cm2(g)

-

Steam Temperature: Saturated & super heated upto 380° C

-

Fuel : All type of Coal/ Rice Husk/ Lignite/Agro waste/ Wood chips

-

Application: All process heating Industries like Co generation Power plants, Process plants as Paper, Food Process, Rice Mill, Rubber Pharmaceutical, etc.

Special Features

-

Extreme precise optimum fluidization velocity, optimum resistance time & free board height, which leads to instant steam generation

-

For very high ash fuels like Dolochar, washery rejects, etc. Open/Hopper bottom type furnace can be given

-

Multi fuel firing

-

Special drum internals High sulphur, high ash and low CGV fuels can be burnt.

-

Minimized un burnt carbon loss and hence high boiler efficiency.

-

Compartmentalized combustion chamber. Hence better turn down ratio of 1:4.

-

High turbulence of the bed facilities quick start up and shut down.

-

Low SOX and NOX emissions.

-

Under bed and over bed feeding options

-

All necessary safety interlocks for safest operation

-

Very effective steam generation since boiler is designed with suitable evaporation areas for bed coil, water wall, bank tubes.

-

The well-built design effectively brings down maintenance needs that in turn ensure uninterrupted operation.